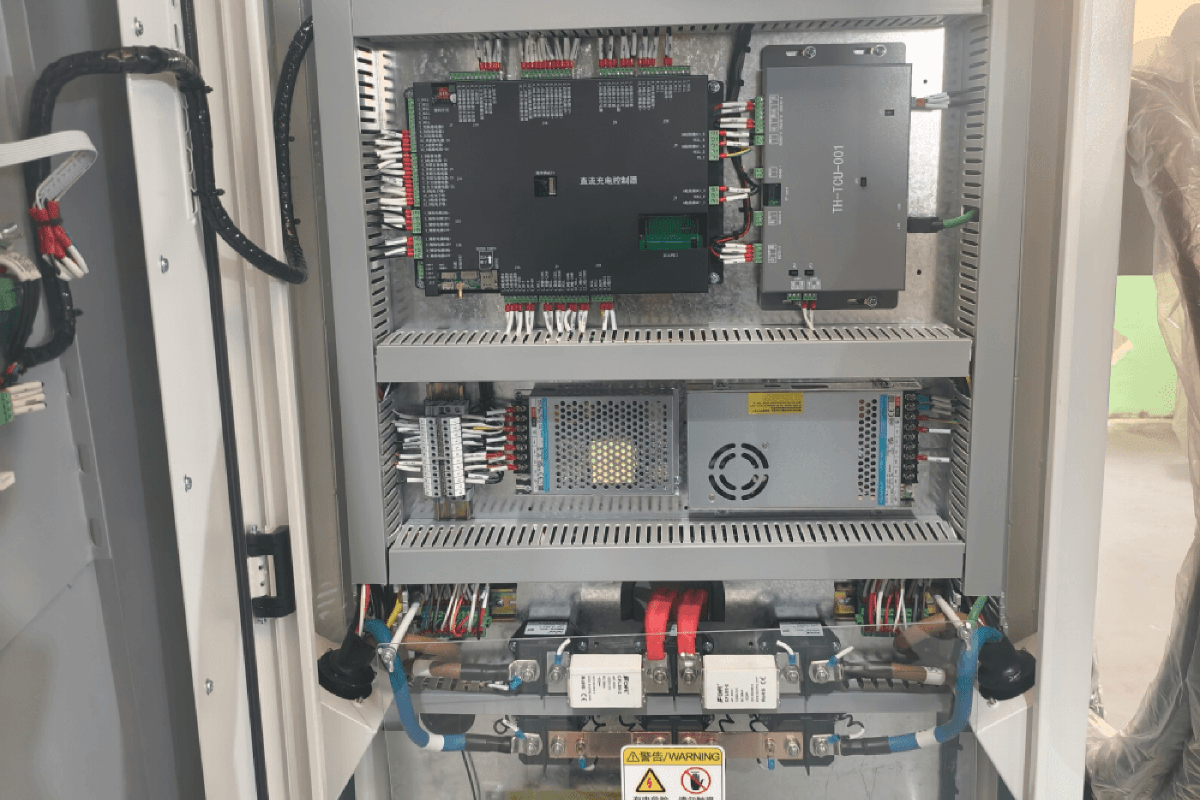

Quick overview — This internal view shows the layout of a production-grade air-cooled DC fast charger: the top area hosts the protocol-conversion and metering units, the middle is the control and communications section, and the bottom handles distribution and protection. We support brand customization of key components (breakers, contactors, SMPS power supplies, terminal blocks, sensors, etc.) and provide OCPP remote operations. The article also explains where 300 A air-cooled charging cables fit, how to choose 120–240 kW DC fast chargers, and when to upgrade to a liquid-cooled system.

Image Structure (top → bottom) Top layer — Protocol & metering unit

Top layer — Protocol & metering unit

From left to right: EMCC protocol converter, dual-channel DC energy meter, 4G/LTE module, and EMCC protocol converter. On the side rail you can see the E-Stop safety-loop terminals; the door magnetic interlock is mounted on the front door frame.

Second & third layers — Main control system + auxiliary power

These layers house the main control board, I/O boards, and the OCPP 1.6J communication interface (wired/4G/Wi-Fi), as well as the 12 V and 24 V auxiliary SMPS power supplies.

Fourth layer — DC interruption & measurement

DC contactors, DC fuses, and shunt/current sensors provide safe make/break on the 200–1000 V DC busbar and accurate current feedback, enabling firmware-based current limiting / power derating.

Bottom layer — Distribution & protection

MCCB/MCB breakers, an AC contactor, terminal blocks, and the PE grounding busbar. Space is reserved for cable glands and gun harness routing to simplify service.

Why Choose an Air-Cooled DC Fast Charger

For 60–240 kW single-cabinet deployments (dealers, fleets, logistics parks), air-cooled systems offer high cost-performance and simple maintenance.

A typical 300 A air-cooled cable on 800 V EVs provides instantaneous power ≤ 240 kW. If you need higher power or a lower handle temperature, consider a 500–600 A liquid-cooled solution.Thermal behavior: fans and temperature sensors protect the power stage; when thermal headroom is limited, the firmware automatically derates output.

Brand-Customizable Components (per project)

To match local spare-parts and maintenance practices, we can adjust the BOM (subject to supply and compliance):

Breakers / contactors / SPDs: e.g., ABB / Schneider Electric / Eaton (MCCB, contactors, surge protection).

Aux power & relays: e.g., Mean Well (SMPS), Omron / Panasonic (relays).

Terminal blocks & accessories: Phoenix Contact / Weidmüller, etc.

Control, Safety & Remote Operations

OCPP 1.6J (upgrade option toward 2.0.1): remote start/stop, pricing/tariffs, OTA firmware updates, alarms, multilingual HMI.

Safety mechanisms: over-voltage / over-current / over-temperature protection, ground-fault detection, insulation monitoring, door magnetic interlock, emergency stop.

Field buses: RS485/Modbus to external devices and cooling units (read coolant temperature/flow, control fan/pump speed); Ethernet to the CSMS; DI/DO for site logic and payment peripherals (where supported).

Data & BI: export session logs, energy, faults, and availability/SLA data to dashboards.

Air-Cooled DC Fast Charger Sizing Guide

|

Application scenario |

Recommended power |

Connector type |

Notes |

|

Dealer delivery / PDI bay |

60–120 kW |

CCS2 / GB/T / CCS1 |

Low noise, short charging sessions |

|

Fleet parking (400 V / 800 V mix) |

120–180 kW |

CCS2 / CCS1 |

Balance dwell time with cable current capability |

|

Logistics / industrial park |

180–240 kW |

CCS2 / GB/T |

Consider group charging or on-site ESS for peak shaving |

|

Highway service area (cost-first phase) |

240 kW |

CCS2 |

Plan an upgrade path to liquid-cooled |

When to Upgrade to Liquid Cooling

When sustained single-gun power > 240 kW is required.

In extremely hot climates, or when you need lower handle temperature and lower acoustic noise.

For most fleet/commercial projects, air-cooled chargers still win on TCO and maintenance simplicity.

Typical Specifications (air-cooled DC fast charger)

Output power: 60 / 120 / 180 / 240 kW (scalable).

Output voltage/current: 200–1000 V; typical air-cooled single cable up to 300 A.

Connectors: CCS2 / CCS1 / GB/T (project-selectable).

Cooling: Module air cooling + filtered airflow path.

Protection class: IP54 cabinet.

Communications: OCPP 1.6J (4G / wired).

Functions: RFID authentication; local / offline / remote operating modes.

Best-Fit Application Scenarios

Dealers & rental companies (fast vehicle turnaround).

Fleets & logistics hubs (controlled dwell time, time-of-use billing).

Campuses / industrial parks (shared infrastructure with OCPP billing).

Municipal & public parking (start with 120–240 kW, expand later).

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.