Municipal Bus Charging Solution

To fulfill an urgent request from one of our U.S. clients. The unstable power supply in the client's area has caused a local brand bus to frequently fail to use the fixed charging stations for replenishment, which has seriously affected its daily operation. The client wants us to provide a stable, efficient and flexible charging solution.

During the initial communication, we realized that the client's actual demand is to provide full power service for 2 to 3 buses, with an average battery capacity of 80kWh per bus. From the perspective of cost-effectiveness and utilization efficiency, we initially recommended a mobile charging system consisting of a 161kWh energy storage battery and a 120kW charging pile. The solution has good mobility and compatibility, and is able to provide stable charging services for electric buses in a variety of scenarios.

However, further feedback from the client was that the local power was not only unstable, but also had frequent power outages, making it impossible to rely on three-phase AC power to replenish the equipment. At the same time, the equipment will be deployed in the suburbs, and it will be extremely inconvenient to use AC power to replenish energy. Therefore, the client proposed to cancel the AC charging port and replace it with a dc charger ev for quick charging of the equipment, and then use a trailer to transport the equipment to the service area for charging the vehicles.

In addition, the client specifically pointed out that due to the high price of copper in the region, the charging guns were frequently stolen, and requested that the equipment adopt a socket-type charging gun design in order to reduce the risk of theft. However, this requirement is a brand new challenge for our company. Due to the high current of DC charging pile, there are almost no socket type DC gun holders on the market that meet the safety standard. However, based on the service concept of “client-oriented”, our company decided to customize a new solution for the client.

After a number of technical discussions and program optimization, and finally agreed with the client to determine the following configuration:

- ✅ Energy storage battery capacity: 372kWh

- ✅ Charging pile power: 120kW, support detachable gun line

- ✅ Recharge mode: cancel AC recharge, only support dc charger ev connected through the national grid for fast recharge

- ✅ Transportation mode: use trailer transportation, improve equipment mobility

- ✅ Charging interface: customized socket DC charging gun to meet client anti-theft needs

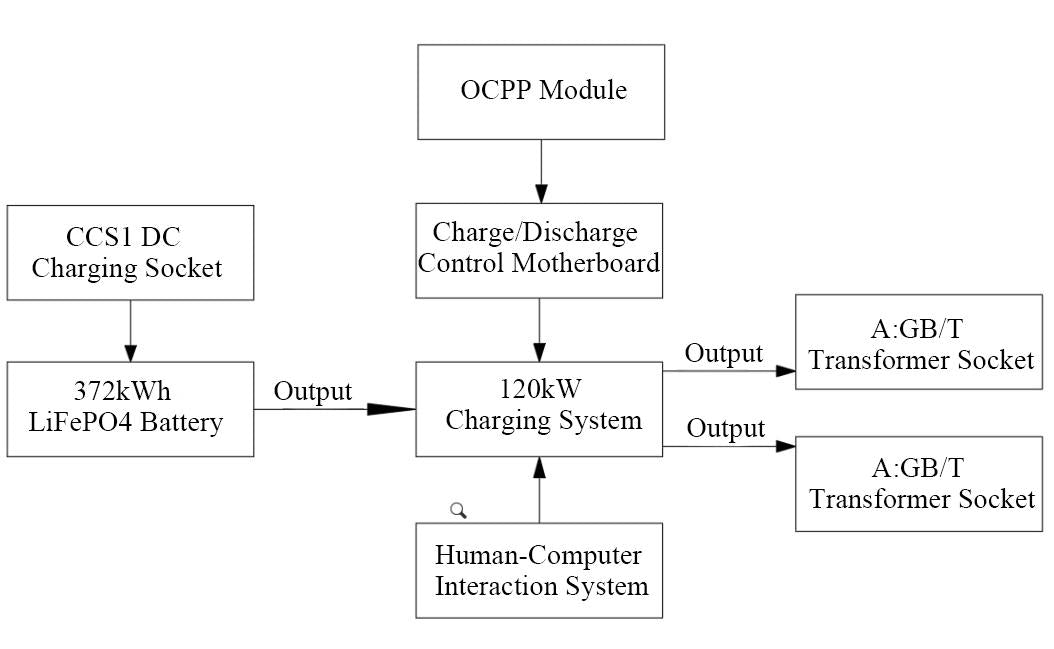

equipment topology map and submitted it to the client for review at the first time, which was highly recognized by the client.

This mobile energy storage charging system consists of several core modules including:

- ✅ Energy storage system: adopts high energy density batteries with long life and high safety

- ✅ Human-machine interaction system: equipped with touch screen, easy to operate and friendly interface

- ✅ Power metering module: accurate recording of charging data, convenient for management and billing

- ✅ Power Conversion System (PCS): realizes high efficiency of power conversion and output

- ✅ Communication module: supports remote monitoring and data transmission, convenient for operation and maintenance management

- ✅ Charging interface: customized socket type DC gun, taking into account the needs of security and anti-theft.

In terms of safety, the system is equipped with multiple protection mechanisms, including double safety protection for input and output, real-time monitoring of battery voltage and current, and cable connection status detection. Once abnormal connection or system failure is found, the equipment will immediately terminate the discharge to ensure personal and vehicle safety. At the same time, the system also has a humanized interface guidance function, users can easily complete the entire charging process.

The electrical parameters are as follows:

| No | Term | Parameter | Note |

|---|---|---|---|

| Single cell parameter | |||

| 1. | Battery Type | Square shape LiFePO4 | |

| 2. | Rated Voltage / Capacity | 665.6V280Ah | 1 parallel 208 strings |

| 3. | Voltage Range | 2.5V–3.65V | |

| 4. | Weight | 4300Kg | |

| 5. | Size | 204.4*174*71.7mm | Height-Width-Thickness |

| 6. | Operating Temperature | Discharge-20℃to+55℃ Charge-0℃to+55℃ |

|

| 7. | Number of Cycles | More than 3500 times (1C cycle, at room temperature, capacity retention rate: 80%) |

|

| Packed Battery Parameter | |||

| 1. | Group Type | 665.6V280Ah | |

| 2. | Total Electric Power | 372.73KW | |

| 3. | Maximum Continuous Charging Current | 140A | The BMS system intelligently adjusts according to different SOCs and different temperatures of the battery |

| 4. | Maximum Continuous Discharge Current | 280A | |

| Basic Charging System Parameters | |||

| 1. | Charge Gun Cable Length | 7m | |

| 2. | Charge Gun Auxiliary Power Output | 12V | |

| 3. | Size | 2888.3*1574*8093mm | L*W*H, excluding gun cable and coiled wire dimensions |

| Input Characterization | |||

| 1. | DC Input Voltage | 200V-1000VDC | |

| 2. | DC Input Current | 0~140A | CCS1 charging port, energy storage battery recharges itself |

| Output Characterization | |||

| 1. | Output Voltage Adjustment Range | 200V-1000VDC | Meet the charging of passenger cars, buses and trucks |

| 2. | Output Current Adjustment Range | 0-400A | The system intelligently adjusts the output current according to the state of the storage battery. |

| 3. | Efficiency | ≥95% | |

| 4. | Total Output Power | 120KW | |

| Protecting Characteristics | |||

| 1. | Input Under-voltage Protection Point | 200VDC | |

| 2. | Input Over-voltage Protection Point | 1000VDC | |

| 3. | Input Over-current Protection | YES | |

| 4. | Output Over-voltage Protection | YES | |

| 5. | Output Over-current Protection | YES | |

| 6. | Short Circuit Protection | YES | |

| 7. | Over-temperature Alarm | 50-60℃ | |

| 8. | Over-temperature Protection | 60℃ | |

| 9. | Charge Gun Over-temperature Alarm | 90℃ | |

| 10. | Charge gun Over-temperature Protection | 105℃ | |

| 11. | Emergency Shutdown Protection | YES | |

| 12. | Soft Start Time | 5-10 seconds | |

| 13. | Human-Machine Interface (HMI) | YES | 10.0 inch |

At present, the equipment has completed production and has been successfully delivered to the client.

The success of this project not only reflects our technical strength in the field of new energy charging, but also highlights our ability and determination to provide customized solutions for our clients.In the future, we will continue to uphold the concept of “technological innovation, service first” to provide global clients with smarter, more efficient and safer charging products and solutions.