A practical, readable guide for drivers, fleet managers, and site operators

At 7:00 am. , Tao, a depot manager, does his morning walk-through. Two vans queue up to top off. A driver asks:

“Boss, are we going to that new ev charging station 180kW DC fast again? People say frequent DC fast charging will ruin the battery.”

Tao smiles. “Speed isn’t the same as abuse. What really matters is temperature, the SOC window, and how the car’s battery management plays along.”

That, in one line, is the answer.

A straight, useful conclusion

DC fast charging is not inherently damaging. Battery aging is driven by temperature, charge rate (C-rate), time spent at high SOC, and thermal management—not by the word “DC.”

A compliant dc fast charger and the vehicle’s BMS taper power as SOC rises (the CC-CV profile). That “slowing down” near full isn’t a flaw—it’s protection.

The real risk scenario is high temperature + near-full SOC + long parking. Even slow AC charging can age cells faster if you leave the car full in the heat.

Want to go deeper? Check the standards that define how chargers and cars “talk” and how tapering works at high voltage: IEC 61851-23/24, IEC 62196, SAE J1772, and GB/T 27930. These are good orientation points rather than SEO bait.

Why the “fast = harmful” myth persists

1.Scary nameplate numbers. Seeing ev fast charger 240kW CCS2 can spook people. In reality, the car decides how much it will accept. Many models take high power roughly in the 20–60% SOC band and naturally taper after ~80%.

2.Temperature is the boss. In hot weather, every charging method needs care. Vehicles pre-heat or pre-cool packs; stations (especially 300 A air-cooled cables) automatically derate when heat builds.

3.Context is ignored. A quick top-up from 20→70% is not the same as running to 1% on a hot day, then blasting to 100% and leaving it full for hours.

Three common questions—answered with real scenarios

Q1: If I use DC fast charging almost every day, will aging skyrocket?

If you routinely arrive very low, then fast charge to 100% under high ambient heat and leave it full, yes, that pattern is harsher.

But if you top up in the mid-SOC band (say 25%→75%) with decent thermal control, the difference is far smaller than people think. Many fleet datasets show this “top-up fast charging” yields good turnaround and healthy packs.

Q2: Do bigger chargers automatically cause more damage?

Not necessarily. The same car on an ev fast charger 120kW CCS2 and on an ev dc fast charging station 150kW CCS2 may draw similar real power, because the BMS limits by temperature and SOC.

When choosing stations, start with what your vehicles actually accept, then look at thermal design and serviceability.

Q3: In winter fast charging slows down—is the station weak?

Usually the car is protecting itself. Low temperature raises internal resistance; the BMS pre-heats or limits current, then opens the tap as the pack warms. That’s also battery care in action.

Action lists that actually help

For drivers

·Treat DC as a top-up tool. Most days, charge in the 20–80% window and leave when it’s “enough.” For road trips or overnights, then go to 100%.

·Mind temperature. Prefer covered/night sessions in summer; avoid letting the car sit at 100% in heat.

·Use preconditioning via navigation. Many models warm/cool the pack en route, making fast charging both faster and kinder.

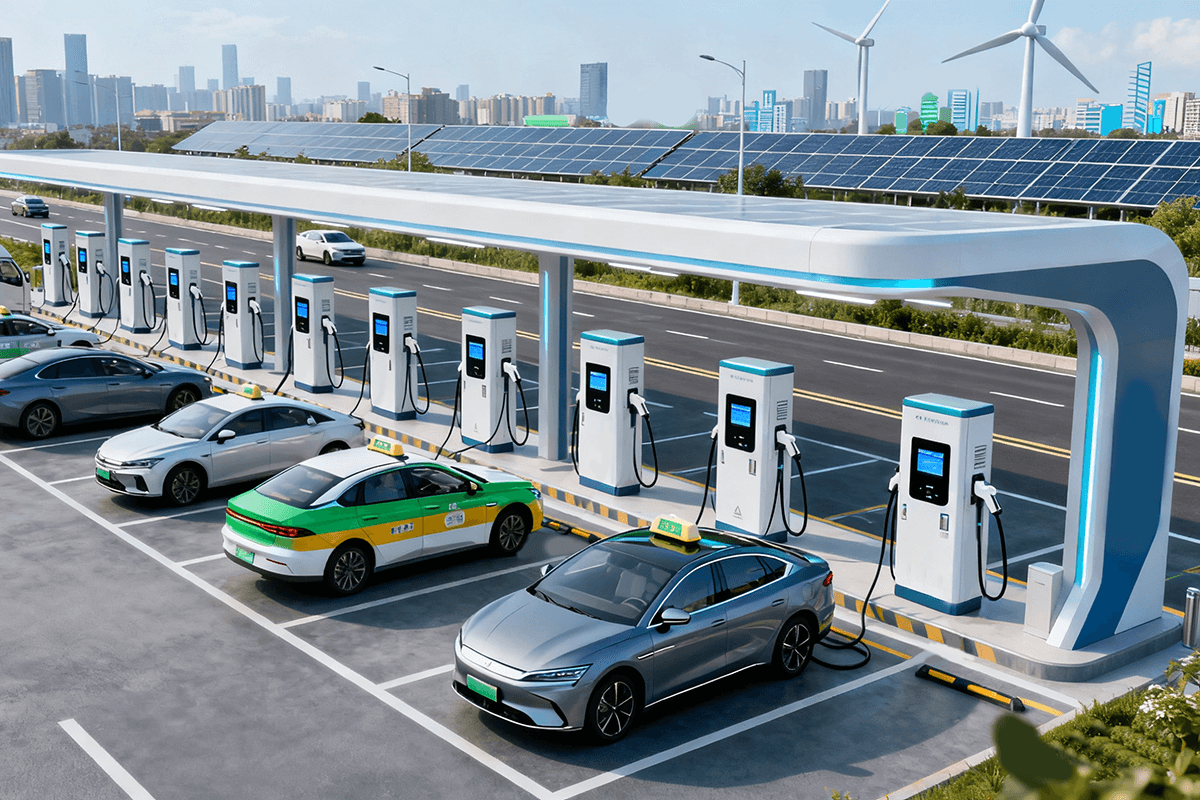

For fleets/operators

·Size to “vehicle-accepted power.” If your main fleet peaks around 170–190 kW, prioritize 180 kW provisioning (e.g., an ev charging station 180kW DC fast). For mixed fleets, combine power levels and guns with smart scheduling.

·Thermal first. Keep filters/air paths clean in hot seasons; plan liquid-cooled cable upgrades where long high-power sessions are routine.

·Consistent UX. Set a “top-up first” policy station-wide; on-screen hints that “20–80% is fastest” save driver time and battery stress.

Choosing stations that are quick and gentle

·Daily use at malls/campuses: 120–180 kW tiers are usually ideal for single-vehicle top-ups.

·Highway and queue-averse sites: 240 kW can be a good starting tier, but served vehicles in parallel and thermal stability matter more than the number on the sign.

·Multi-standard reality: If you handle both GB/T and CCS2, consider mixed-connector configurations—e.g., pairing ev fast charger 150kW GB/T with CCS2 as your market requires.

Practical pointer: if your main models accept ~170–190 kW peaks, design around that behavior rather than chasing bigger nameplates. Keep air-cooled paths clean; in extreme summers, plan for liquid-cooled handles where duty cycles demand it.

Solid places to learn more

·Standards protocols: IEC 61851-23/24 (DC system comms), IEC 62196 (interfaces), SAE J1772, GB/T 27930.

·Automaker cell-maker white papers: useful on thermal windows, charge curves, and life trade-offs.

·Academic reviews: search Journal of Power Sources, Journal of Energy Storage, Applied Energy for “fast charging degradation” and “temperature/SOC aging.”

·Across these sources you’ll see the same theme: time at high SOC × temperature dominates aging, while standardized fast-charge control is designed to protect.

Closing thought: “Fast” vs “gentle” is a false choice

DC fast charging is like a chef who knows the flame: high heat doesn’t mean burnt food. With a standards-compliant dc fast charger cooperating with the car’s BMS, picking the right top-up window, and minding temperature and parking habits—you get quicker turns and steady battery health, not “sacrificed life for speed.”

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.